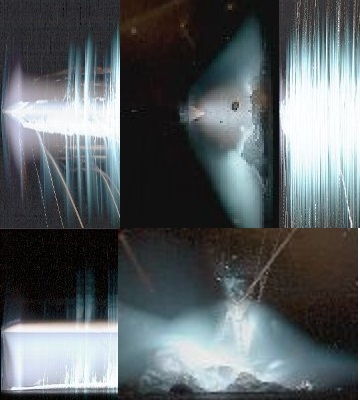

GTA process in Nitrogen

| Typical high-speed movies | |||

|---|---|---|---|

|

|

|

|

| (1)20kfps | (2)2kfps | (3)200fps | (4)Air54kfps |

Right pictureas show time chart of welding process in nitrogen shield. Left hand side pictures are chart of 20ms in arc ignition stage. A left upper chart shows horisontal behavior as shown in middle upper picture. A right upper chart shows behavior in 0.2 seconds of igniton stage.

Right pictureas show time chart of welding process in nitrogen shield. Left hand side pictures are chart of 20ms in arc ignition stage. A left upper chart shows horisontal behavior as shown in middle upper picture. A right upper chart shows behavior in 0.2 seconds of igniton stage.A left lower chart shows vertical behavior of arc ignition stage in 20ms. A right lower picture shows a video behavior in 200ms. Muximum intensities in each pixel are shown among 100 frames of arc ignition stage at 20kfps. Sputters can be recognized as dotted locus in the picture. Cleaning actions on the electrode surface are also recognized in the picture.

Major cleaning action on the cathode is finished in 2ms in this case. Detail analysis of the cleaning action requires more than 200kfps vido rate. Much gas generates from the base metal in arc ignition stage, so suitable arc channel generates quickly. Then the period of cleaning action is limited in this casse.

Captured video frame rate is 20kfps. Effective video rate are 2kfps in Lower videos. So, there are opotunity to proceed the image information of 10 frames.

(2-1)This movie uses maximum value among 10 frames.

(2-2)This movie uses mean value among 10 frames.

(2-3)This movie uses minimum value among 10 frames.

(2-4)This movie uses difference between maximum and minimum value among 10 frames.

|

|

|

|

| (2-1)2kfps_max | (2-2)2kfps_mean | (2-3)2kfps_min | (2-4)2kfps_dif |

(2-1)This movie uses maximum value among 100 frames.

(2-2)This movie uses mean value among 100 frames.

(2-3)This movie uses minimum value among 100 frames.

(2-4)This movie uses difference between maximum and minimum value among 100 frames.

|

|

|

|

| (3-1)200fps_max | (3-2)200fps_mean | (3-3)200fps_min | (3-4)200fps_dif |

2016.09.02open,Å@2016.09.02revised