1. INTRODUCTION (Consumable or not consumable / basic knowledge)

A tungsten cathode with inert gas welding is called as non consumable electrode.

Consumption rate is quite low in proper welding condition. However, I had strated my research carrier for underwater welding and cutting. In this field, consumption of tungsten cathode in high pressure conditon was quite a problem as shown in right figure. Errosion rate of tungsten cathode is high. GTAW is used for first layer welding for connecting pipe. It takes almost one hour to complete joining od pies. The erosion in herium shield is much larger than for argon shield. We had to change electrode sometime to complete welding. It was troublesome to change the electrode during welding in high pressure condition.

A tungsten cathode with inert gas welding is called as non consumable electrode.

Consumption rate is quite low in proper welding condition. However, I had strated my research carrier for underwater welding and cutting. In this field, consumption of tungsten cathode in high pressure conditon was quite a problem as shown in right figure. Errosion rate of tungsten cathode is high. GTAW is used for first layer welding for connecting pipe. It takes almost one hour to complete joining od pies. The erosion in herium shield is much larger than for argon shield. We had to change electrode sometime to complete welding. It was troublesome to change the electrode during welding in high pressure condition.

One major problem for erosion is a contamination of oxygen in the shielding gas. Oxidation of hot tungsten cathode is serious problem. Melting and evaporating temperatures of tungsten oxide is quite low compared with tungsten iteself as shown by red number in right table.

Another problem of tungsten cathode is its work function. Tungsten itself has superior ability to emit electrons in welding process. However, its work function is rather low to produce enough current density for welding process. Welding process requires quite high current density, and then, tungsten cathode temperature must be higher than its melting point to produce enough current for welding. A movie of this situation can be watched by

clicking on a right image. You will watch rapid melting asd dropping of molten tungsten on a base metal. Inclusion of molten tungsten in weld metal causes some weakness of joint metal property. Some percent of minor element for example thorium oxide(Thoria), celium oxide or lantan oxide is added into tungsten to improve electron emitting property. So, pure tungsten cathode rarely used in normal welding process.

clicking on a right image. You will watch rapid melting asd dropping of molten tungsten on a base metal. Inclusion of molten tungsten in weld metal causes some weakness of joint metal property. Some percent of minor element for example thorium oxide(Thoria), celium oxide or lantan oxide is added into tungsten to improve electron emitting property. So, pure tungsten cathode rarely used in normal welding process.Considerable amount of tungsten oxide evaporate above arc region. And some desociated tungsten atom hit on the cathode surface. Then, dendrite crystal as called "RIM" is constructed between arc region and evapration area. You can watch this situation by

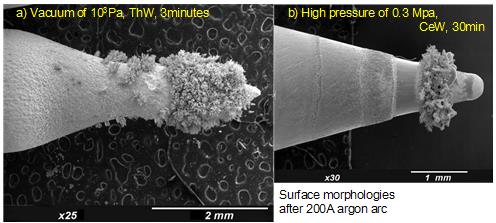

clicking on a right image. Typical eroded cathodes in high pressure in 0.3MPa and low pressure in 1000Pa by oxidation are shown in right. Electerons and ions can be reached large area by less collision in vacuum condition, so large area of the cathode are eroded. On the contrary, reachable region of electrons and ions are quite short in high pressure, the eroded area of the cathode is limited as shown in images on below.

clicking on a right image. Typical eroded cathodes in high pressure in 0.3MPa and low pressure in 1000Pa by oxidation are shown in right. Electerons and ions can be reached large area by less collision in vacuum condition, so large area of the cathode are eroded. On the contrary, reachable region of electrons and ions are quite short in high pressure, the eroded area of the cathode is limited as shown in images on below.

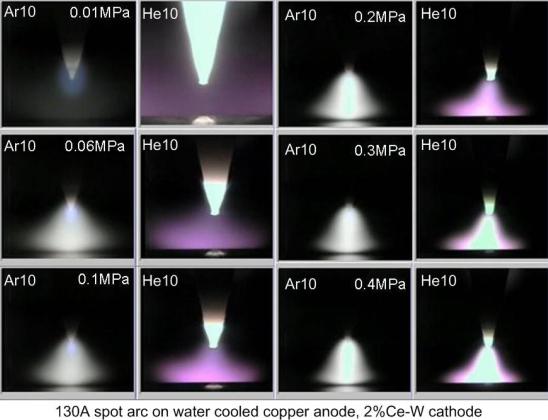

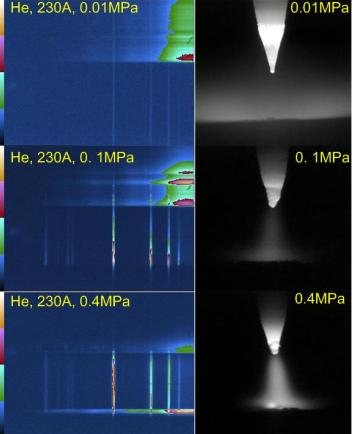

Typical arc images in helium and argon at various pressure range are shown in below pictures. Arc configurations in helium shied and it in argon sgield are different in normal welding process on the earth ground. It is easy to think hwy an errosion in vacuum condition is so large. This errosion causess by oxygen contamination in the experimental vacuum chamber.

Arc is concentrared in high pressure, on the other hand, arc is spread in low pressure. Hot plasma particles including atoms, ions and electrons hit on the cathode in large area in vacuum condition. Then the cathode surface temperature rases remarkably. The above pictures are captured by color camera. Right pictures are captured by monochrome camera with spectro-scopic prism and narrow band-pass filter. Left images are spectra on the center line of the electrode and arc. Right pictures are captured through narrow band-pass filter of 950nm. Captured conditions are the same for all arcs, then the brightness shows the temperature difference. The brightness of spectra is low, the pseude color painting are processed to show the deference. Hot area on the cathode are regions of thoria is melted.

Arc is concentrared in high pressure, on the other hand, arc is spread in low pressure. Hot plasma particles including atoms, ions and electrons hit on the cathode in large area in vacuum condition. Then the cathode surface temperature rases remarkably. The above pictures are captured by color camera. Right pictures are captured by monochrome camera with spectro-scopic prism and narrow band-pass filter. Left images are spectra on the center line of the electrode and arc. Right pictures are captured through narrow band-pass filter of 950nm. Captured conditions are the same for all arcs, then the brightness shows the temperature difference. The brightness of spectra is low, the pseude color painting are processed to show the deference. Hot area on the cathode are regions of thoria is melted.next pageÅ@Å@Å@2016.10.7open,Å@2016.10.10revised