6.x Arc ignition behavior of pure tungsten electrode

前ページ

| 200107Arc ignition by pure tungsten electrode |

|---|

|

|

|

|

|

|

|

|

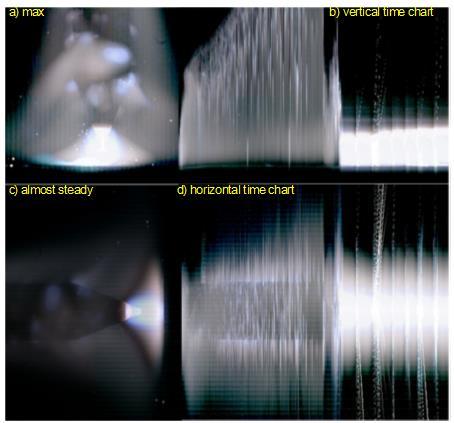

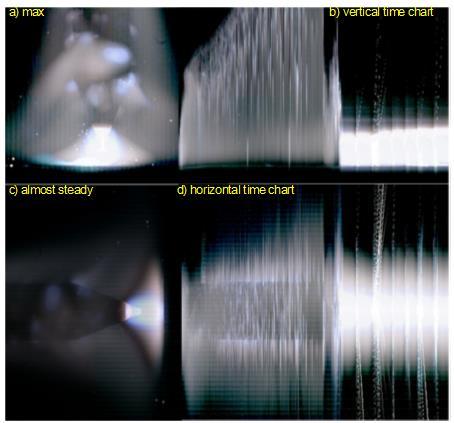

Arc ignition behavior by pure tungsten electrode is well known as cleaning action. It takes some time to maintein main arc between the cathode and the base metal. The cleaning action is too quick to observe normal video vamera.

Recent ultra high-speed video can easily capture precise phenomenon of cleaning action as shown in the right-hand pictures. Click one of above pictures, then you can watch movies in arc ignition stage.

Solid tungsten cathode cannot provide enough current density for arc welding. Arc current can be provided when the tungsten cathode is melted. Some molten tungsten dropps in to the base metal.

There are so many iluminated spots on the tungsten surface, simultaneously. A video rate of 20kfps is not enough to identify, that many spots are existed in the same time or not.

These video show typical drawbacks of the pure tungsten electrode. Some percent of thoria is added to improve arc characteristics.

Appropriate arc current can be produced from solido cathode top by additing of thoria. However cleaning action is still existed for thoriated tungsten electrode.

High-sped video is very effective tool to understand trangent behavior. Major problem for high-speed video is time. Long time observation is required.

Pseudo color system is good way to understand quantitative behavior of arc ignition. Some image treatments to shorten the watching time are processed. "2kdif" video shrnks te images to one, so watching time can be reduce to 10%. "2kmax" video shows the highest brightness among 10 images. "2kdif"" video shows the highes difference of each image.

Pseudo color system is another solution to clarify the quality and quantity of observed process.

次ページ 2016.09.30作成 2016.09.30改定

Pseudo color system is good way to understand quantitative behavior of arc ignition. Some image treatments to shorten the watching time are processed. "2kdif" video shrnks te images to one, so watching time can be reduce to 10%. "2kmax" video shows the highest brightness among 10 images. "2kdif"" video shows the highes difference of each image.

Pseudo color system is good way to understand quantitative behavior of arc ignition. Some image treatments to shorten the watching time are processed. "2kdif" video shrnks te images to one, so watching time can be reduce to 10%. "2kmax" video shows the highest brightness among 10 images. "2kdif"" video shows the highes difference of each image.